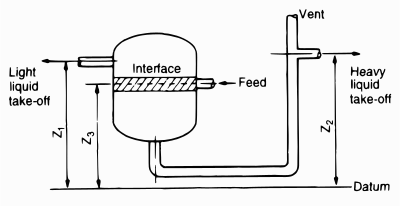

Sizing of a Vertical Decanter

Decanters are used to separate liquids where there is a sufficient difference in density between the liquids for the droplets to settle readily. Decanters are essentially tanks which give sufficient residence time for the droplets of the dispersed phase to rise (or settle) to the interface between the phases and coalesce. In an operating decanter there will be three distinct zones or bands: clear heavy liquid; separating dispersed liquid (the dispersion zone); and clear light liquid.

Source: Coulson & Richardson's Chemical Engineering: Vol. 6. Oxford: Elsevier Butterworth-Heinemann, 2005.

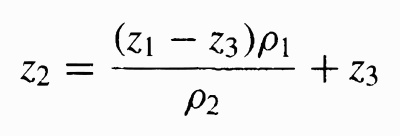

Equation to determine the height of heavy liquid outlet:

Type the required values to get the outlet height of a decanter:

Feed/interface height (z1, m)

Light liquid height (z3, m)

Heavy liquid density (ρ2, kg/m3)

Light liquid density (ρ1, kg/m3)

Heavy liquid take-off height (z2, m) [Calculation Output]

Decanter Diameter and Length Calculation

An approximation for a vertical decanter volume can be made by taking a hold-up volume of 5-10 minutes. The decanter vessel is sized on the basis that the velocity of the continuous phase must be less than settling velocity of the droplets of the dispersed phase. Plug flow is assumed, and the velocity of the continuous phase calculated using the area of the interface. Stoke's law is used for calculation of the droplets settling velocity.

Source: Coulson & Richardson's Chemical Engineering: Vol. 6. Oxford: Elsevier Butterworth-Heinemann, 2005.

Type the required values to get the sizing of a decanter:

Oil flow rate (kg/h)

Water flow rate (kg/h)

Oil density (ρoil, kg/m3)

Water density (ρwater, kg/m3)

Oil viscosity (ρoil, kg/ms)

Water viscosity (ρwater, kg/ms)

Vessel diameter (m) [Calculation Output]

Vessel height/length (m) [Calculation Output]

Dispersion band (m) [Calculation Output]

Residence time of droplets in dispersion band (s)

Velocity of oil phase (m/s)

Entrained droplet size (μm)